Main issue

Fouled Air Cooled heat exchangers lead to the

following main failures:

- LOW heat transfer efficiency

- LOW pressure drop

- High cooled fluid outlet temperature

- High energy consumption (Fan power)

- Low cooled fluid throughput

- Low efficiency

- Damage fins (from high pressure)

The client have to consider the cleaning process when thousands of dollars are sent to the flare.

How do we process?

The Air Coolers-Solution On-line cleaning treatment is based on low-pressure spraying of GLOBAL Treatment Chemicals, directly onto the aluminium tubes bundles. This process is a unique combination of both Chemical and Mechanical cleaning.

- GLOBAL Treatment Chemicals are granular solids, sprayed onto the bundles by compressed air through an air jet.

- While spraying, the electrical motor should be turned off for a short period of time, approximately 20 minutes. Other motors can work.

- This way of On-Line cleaning can be done without disturbing the production process.

- While spraying, there is no need for extra scaffolding.

During the On-Line cleaning tratment, the following parameters can be monitored:

- Inlet/outlet temperature of the cooled fluit (DeltaT)

- Power of the fan

- Airflow in the plenum

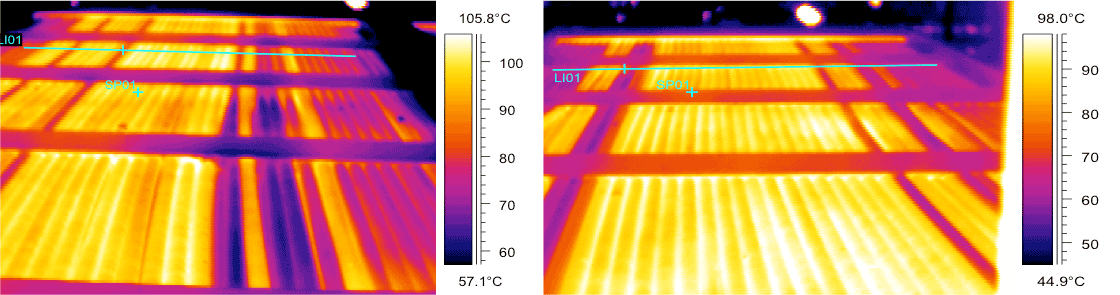

Internal fouling of the tubes

Tubes with reduced / no flow show as colder(darker) . Visually this can be seen as hogged (or distorted/ snaked) tubes. This effect is caused by the tubes that have flow in them being longer (thermal expansion) whilst the cold tubes are still locked into the header boxes that are free to move with the rest (majority) of the hotter tubes.

Visual results

Conclusion

Conclusion of Air-coolers Solution On-Line cleaning tretment:

- Return on investment is immediate and guaranteed.

- Process is SAFE, non-corrosive, non-hazardous.

- Process is environmental-friendly, no environmental impact.